| Items |

1288

0.270 Inch (in) Actual Hose Bore Size Hyperline Hose

|

1289

0.312 Inch (in) Actual Hose Bore Size Hyperline Hose

|

1290

0.394 Inch (in) Actual Hose Bore Size Hyperline Hose

|

1291

0.536 Inch (in) Actual Hose Bore Size Hyperline Hose

|

1292

0.658 Inch (in) Actual Hose Bore Size Hyperline Hose

|

|

Nominal Size

|

N/A

1/4 in

|

N/A

5/16 in

|

N/A

3/8 in

|

N/A

1/2 in

|

N/A

5/8 in

|

|

Actual Bore Size

|

N/A

6.8 mm0.270 in

|

N/A

7.9 mm0.312 in

|

N/A

10.0 mm0.394 in

|

N/A

13.6 mm0.536 in

|

N/A

16.7 mm0.658 in

|

|

Hose Grade

|

N/A

AM SS TO

|

|

Tube or Braid Outside Diameter (TO Hose Grade)

|

N/A

9.0 mm0.354 in

|

N/A

10.0 mm0.394 in

|

N/A

12.5 mm0.492 in

|

N/A

16.2 mm0.640 in

|

N/A

20.0 mm0.787 in

|

|

Tube or Braid Outside Diameter (SS Hose Grade)

|

N/A

9.6 mm0.378 in

|

N/A

10.6 mm0.420 in

|

N/A

13.5 mm0.534 in

|

N/A

17.5 mm0.690 in

|

N/A

21.1 mm0.831 in

|

|

Tube or Braid Outside Diameter (AM Hose Grade)

|

N/A

9.6 mm0.37 in

|

N/A

11.3 mm0.445 in

|

N/A

13.5 mm0.534 in

|

N/A

17.5 mm0.690 in

|

N/A

21.1 mm0.831 in

|

|

Minimum Bend Radius (TO Hose Grade)

|

N/A

38 mm1-1/2 in

|

N/A

38 mm1-1/2 in

|

N/A

50 mm2 in

|

N/A

76 mm3 in

|

N/A

100 mm4 in

|

|

Minimum Bend Radius (SS Hose Grade)

|

N/A

19 mm3/4 in

|

N/A

19 mm3/4 in

|

N/A

25 mm1 in

|

N/A

38 mm1-1/2 in

|

N/A

50 mm2 in

|

|

Minimum Bend Radius (AM Hose Grade)

|

N/A

38 mm1-1/2 in

|

N/A

38 mm1-1/2 in

|

N/A

50 mm2 in

|

N/A

76 mm3 in

|

N/A

100 mm4 in

|

|

Maximum Working Pressure (MWP) (TO Hose Grade)

|

N/A

4 bar60 psi

|

N/A

4 bar60 psi

|

N/A

4 bar60 psi

|

N/A

4 bar58 psi

|

N/A

3 bar44 psi

|

|

Maximum Working Pressure (MWP) (SS Hose Grade)

|

N/A

88 bar1280 psi

|

N/A

88 bar1220 psi

|

N/A

80 bar1160 psi

|

N/A

60 bar870 psi

|

N/A

50 bar730 psi

|

|

Maximum Working Pressure (MWP) (AM Hose Grade)

|

N/A

62 bar900 psi

|

N/A

59 bar850 psi

|

N/A

56 bar810 psi

|

N/A

42 bar600 psi

|

N/A

35 bar510 psi

|

|

Weight Per Unit Length (TO Hose Grade)

|

N/A

0.041 kg/m0.027 lb/ft

|

N/A

0.056 kg/m0.037 lb/ft

|

N/A

0.070 kg/m0.047 lb/ft

|

N/A

0.110 kg/m0.074 lb/ft

|

N/A

0.161 kg/m0.108 lb/ft

|

|

Weight Per Unit Length (SS Hose Grade)

|

N/A

0.092 kg/m0.062 lb/ft

|

N/A

0.126 kg/m0.084 lb/ft

|

N/A

0.160 kg/m0.107 lb/ft

|

N/A

0.225 kg/m0.151 lb/ft

|

N/A

0.336 kg/m0.226 lb/ft

|

|

Weight Per Unit Length (AM Hose Grade)

|

N/A

0.056 kg/m0.038 lb/ft

|

N/A

0.075 kg/m0.050 lb/ft

|

N/A

0.100 kg/m0.074 lb/ft

|

N/A

0.140 kg/m0.094 lb/ft

|

N/A

0.204 kg/m0.137 lb/ft

|

|

Temperature Range

|

N/A

Up to +240 ºC-150 ºC

|

|

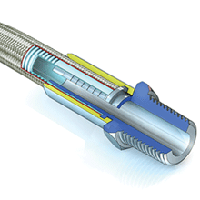

Polytetrafluoroethylene (PTFE) Lined Smooth Bore Flexible Hose

|

N/A

PTFE, or Polytetrafluoroethylene, comprises long-chain molecules of carbon atoms, each linked to two fluorine atoms. The fluorine atoms provide a helical spiral which surrounds the carbon chain and protects it.

It is this structure which creates the unique properties for which PTFE is well-known

|

|

Excellent Chemical Resistance

|

N/A

PTFE is renowned as the most chemically resistant material known. Only a very few, very unusual substances and conditions can affect it, like Fluorine gas at high temperature and pressure and liquid, boiling sodium metal.

PTFE lined hoses can therefore be used for a wider variety of chemicals than any other hose type, making it the ideal choice for very corrosive chemical applications and multi-product applications.

|

|

Non-Stick Surface

|

N/A

The use of PTFE as a surface for cookware products has demonstrated to the world how easily cleanable PTFE surfaces are.

This means that PTFE lined hoses can be purged 100% clean more quickly, easily and reliably than any other type of hose.

|

|

Excellent Temperature Range

|

N/A

The cookware application also demonstrates another of PTFE's many attributes - temperature resistance. PTFE itself can be used as a hose liner at temperatures from -150ºC up to +260ºC, dependent upon the hose design and the application conditions.

This is the widest temperature range of any rubber or plastic hose lining material.

|

|

Hose Design

|

N/A

The only issue with PTFE as a hose lining material is the best way it can be integrated in to the hose design. This is where Aflex Hose have a proven record of success over the last 30 years.

There is a fundamental problem with larger sizes of standard, smooth bore PTFE hose products - as the hose size increases above 1/4", so smooth bore PTFE lined hose become significantly less flexible, and more easily kinked.

One solution is to use a conventional convoluted PTFE lined hose, but the internal convolutions make the hose difficult to assemble, and reduces fluid flow rates due to turbulent flow.

Hyperline FX is a new and revolutionary solution to all these problems, providing a unique and patented hose liner design which is flexible in the larger bore sizes, yet which retains a smooth bore.

The advantage of a smooth bore as compared with a convoluted bore is that it is easy clean, and does not create "turbulent flow", which drastically reduces fluid flow rates.

|